|

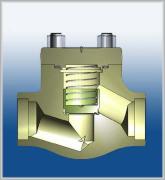

| ** Cryogenic Check Valves |

APPLICATIONS >>>

LNG, Ethylene, Liquid Gas Industry,

Chemical, Petrochemical, Oil Refinery, Gas, Power Plant etc.

FEATURES >>>

* Design - API 600, 602/ BS6364/ ANSI B16.34/ MSS SP 25

* Face to Face & End to End - ASME B16.10/ ISO5752/

BS 2080/ DIN

* Flanged Ends - ASME B16.5/ ISO7005-1/ API 605/

BS 3293/ DIN

* Butt-Weld Ends - ASME B 16.25

* Socket-Weld Ends - ASME B 16.11

* Screwed Ends - ASME B 1.20.1

* Test - API 598

* Solid Long Bonnet/ Inlet Bleed Hole/ Stellite Seat.

MATERIALS >>>

* Cast Steel

ASTM A216 WCB, WCC/ A217 WC1, WC6, WC9

A351 CF8, CF8M, CF3, CF3M, CF8C, CF3MN

A352 LCB, LCC, LC1

* Forged Steel

ASTM A105 Forged Steel

A182 F304, F304L, F316, F316L, F11, F22, LF2, LF3

PRESSURE RATING & SIZE >>>

* API, ANSI, ASME, MSS, BS, DIN, JIS

* 150#~1500# : 1/2"~36"

2500#~4500# : 1/2"~2"

OPERATORS & OPTION >>>

* By-Pass/ Drain Relief etc. |

|

SINER PRODUCTS:

Check Valves :

Swing Check Valves

Tilting Check Valves

Dual Check Valves

Single Disc Check Valves

Hammerless Check Valves

Ball Check Valves

Pressure Seal Check Valves

Cryogenic Check Valves

SINER's valve products have been widdly user\d in petrochemical, gas electric station, food and beverages, papermaking and water treatment etc. The quality and utility of its valve products have been proved. All product categories: Gate Valves, Globe Valves, Check Valves, Ball Valves, Butterfly Valves and Steam Trap,Needle valveare available in both the In-Line and Cartridge styles.

|